Water Chillers

Industrial water chillers at the cutting edge of design

Maziak offers ease of use and peace of mind, thanks to cutting edge technology, proven reliability and an extensive range of versions and accessories.

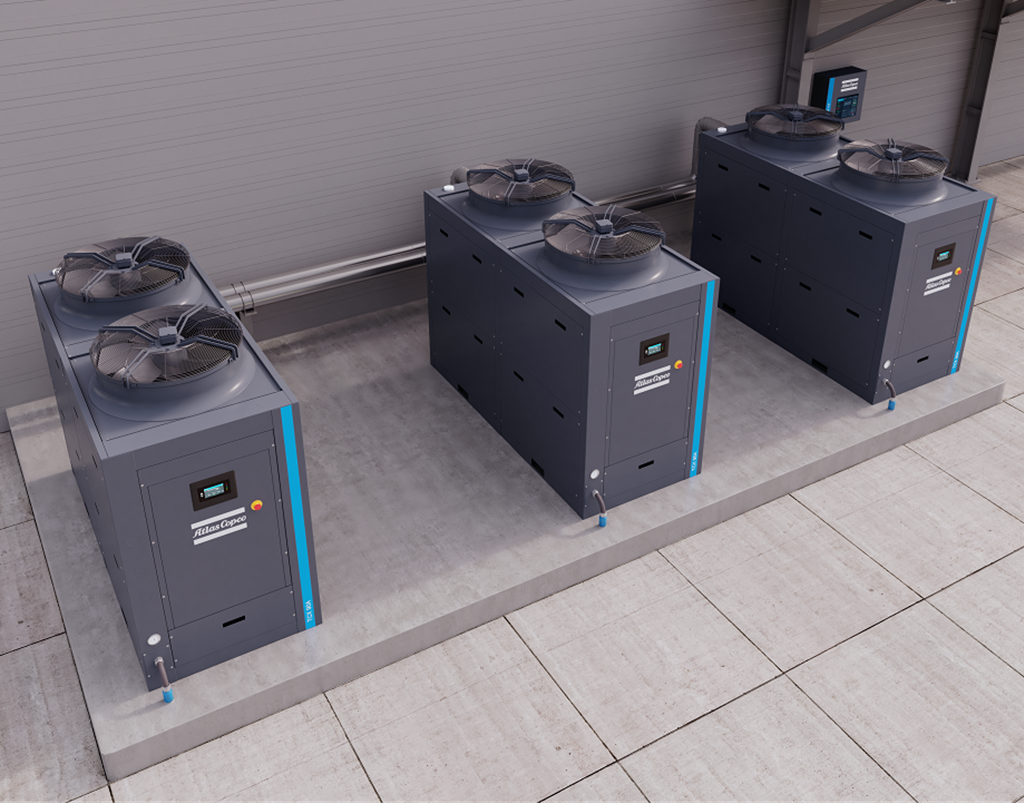

The Atlas Copco TCX & TCA ranges of chillers are specially designed for cooling water (or mixture of water and glycol) for multiple industrial purposes. The TCX4-90 series is a compact, all-in-one water chiller with an air-cooled condenser and integrated hydraulic module, with the ability to precisely control the temperature using an Elektronikon® MkV controller. The pump housing, tank and evaporator are made in stainless steel and the entire chiller is designed for easy maintenance with easily accessible safety components.

For large industrial applications the Atlas Copco TCA55-215 series offers a high level of energy efficiency and supplies complete safety for your day-to-day operations. Reliable and robust, equipped with proven scroll compressors in a twin circuit configuration, air-cooled microchannel condensers and integrated hydraulic module, it provides easy and cost-effective installation and maintenance.

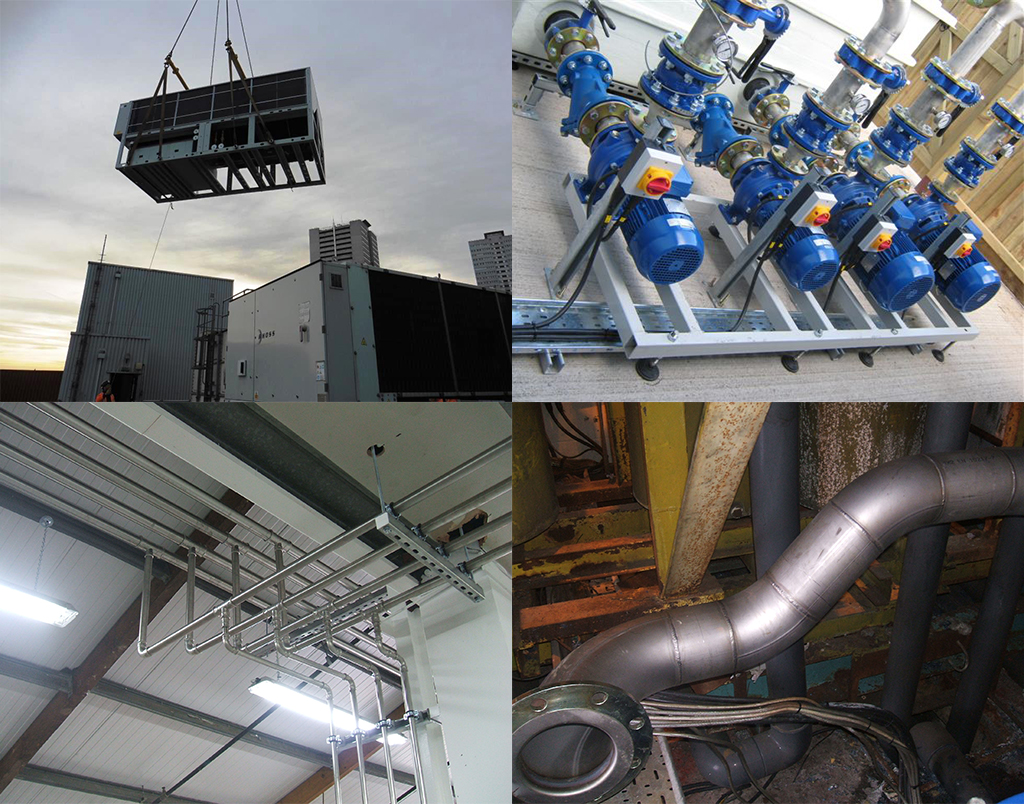

For fully non-ferrous water circuits required for operations such as Medical MRI/CT scanning, we work with other leading manufacturers to offer the optimal solution for your specialist needs. We can also advise on solutions for Laser and Biogas applications.

For more information, please call 01933 222000 or email us at enquiries@maziak.co.uk

_1024x804.jpg#591;text-and-image;1024;804)

_1024x804.jpg#593;text-and-image;1024;804)