The Benefits

YOU can reap the rewards of nitrogen generation—it’s simple with Maziak!

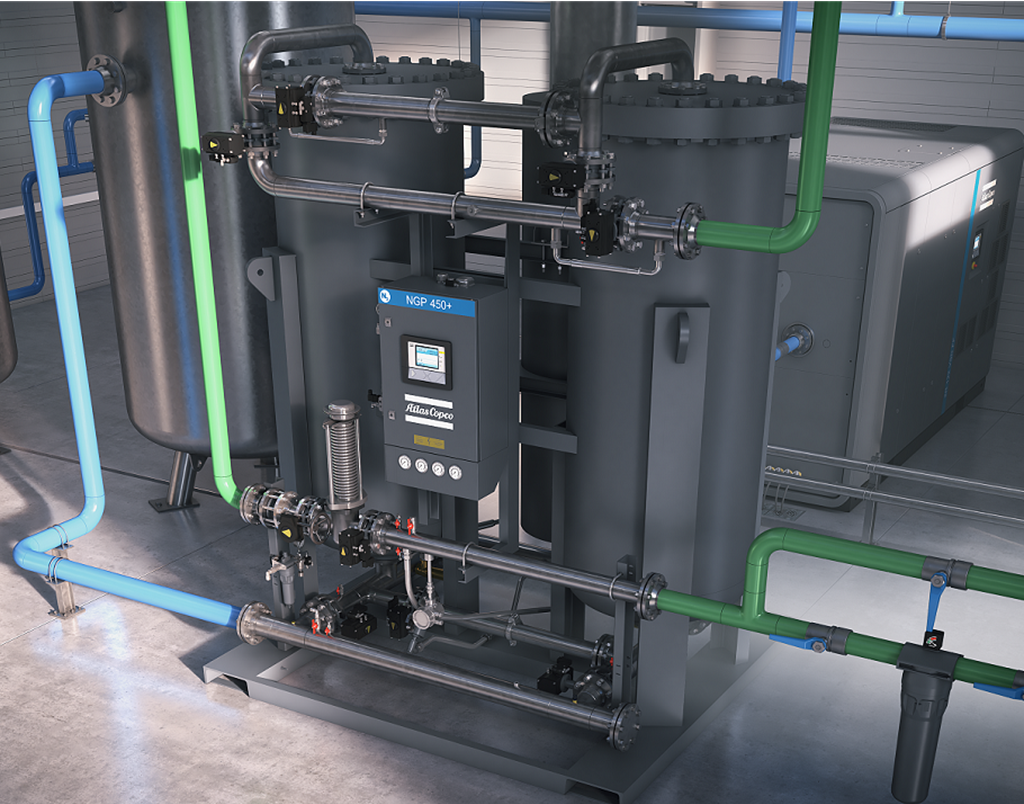

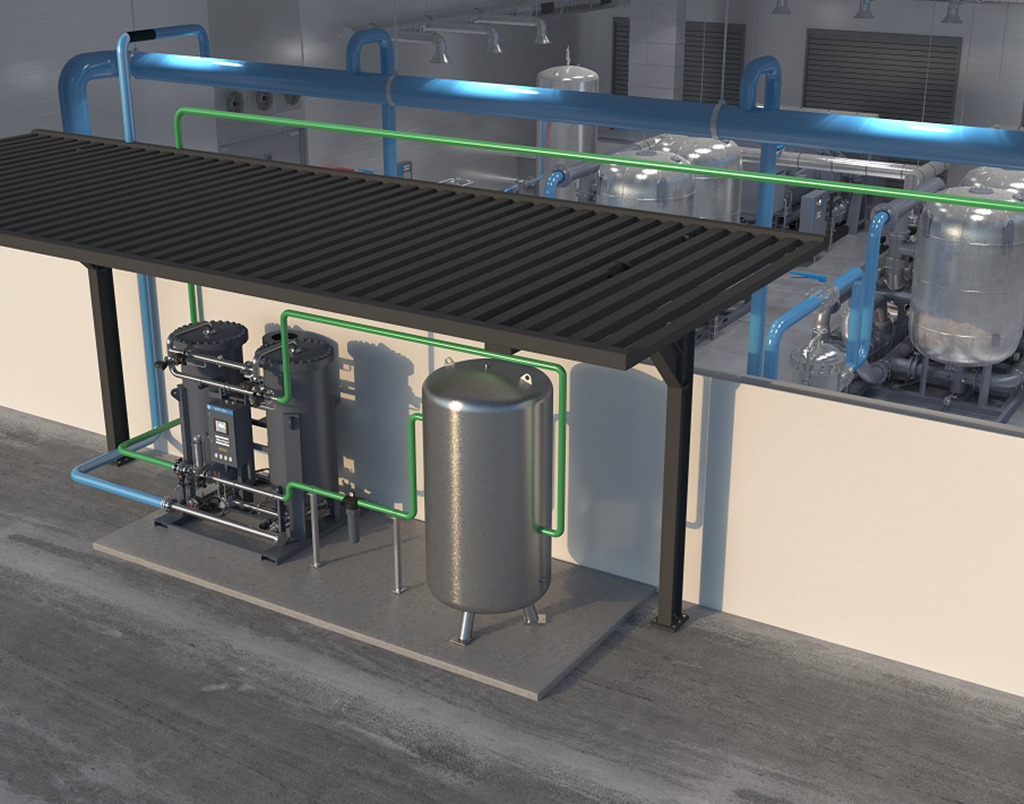

Our nitrogen generation systems continuously produce high purity nitrogen from compressed air and eliminate the inconvenience of a delivered nitrogen supply. Installation is simple: pipe in compressed air and pipe out nitrogen. Just connect a standard compressed air line to the inlet of the generator, connect the outlet to your nitrogen line and the unit is ready for trouble free operation. The system is designed to operate 24 hours/day, 7 days/week. Standard features include high efficiency coalescing prefilters with automatic drains, activated carbon adsorption (when required), nitrogen storage tank and a 0.01 micron final membrane filter. There is also a range of oxygen monitors to measure the oxygen concentration of the nitrogen stream to meet your application requirements. Your onsite nitrogen generation system can be installed to best suit your operation and depending on the application - free standing, housed in a cabinet or skid mounted.

Here's some feedback from one of our satisfied customers: “Maziak's ability to handle the scale of the project was impressive, and even more so is the fact that we hope to achieve payback 12 months from installation and will reduce our annual N2 costs by over 75%.”

The benefits of on-site N2 generation to you are enormous and the payback on investment is very attractive:

You are in control

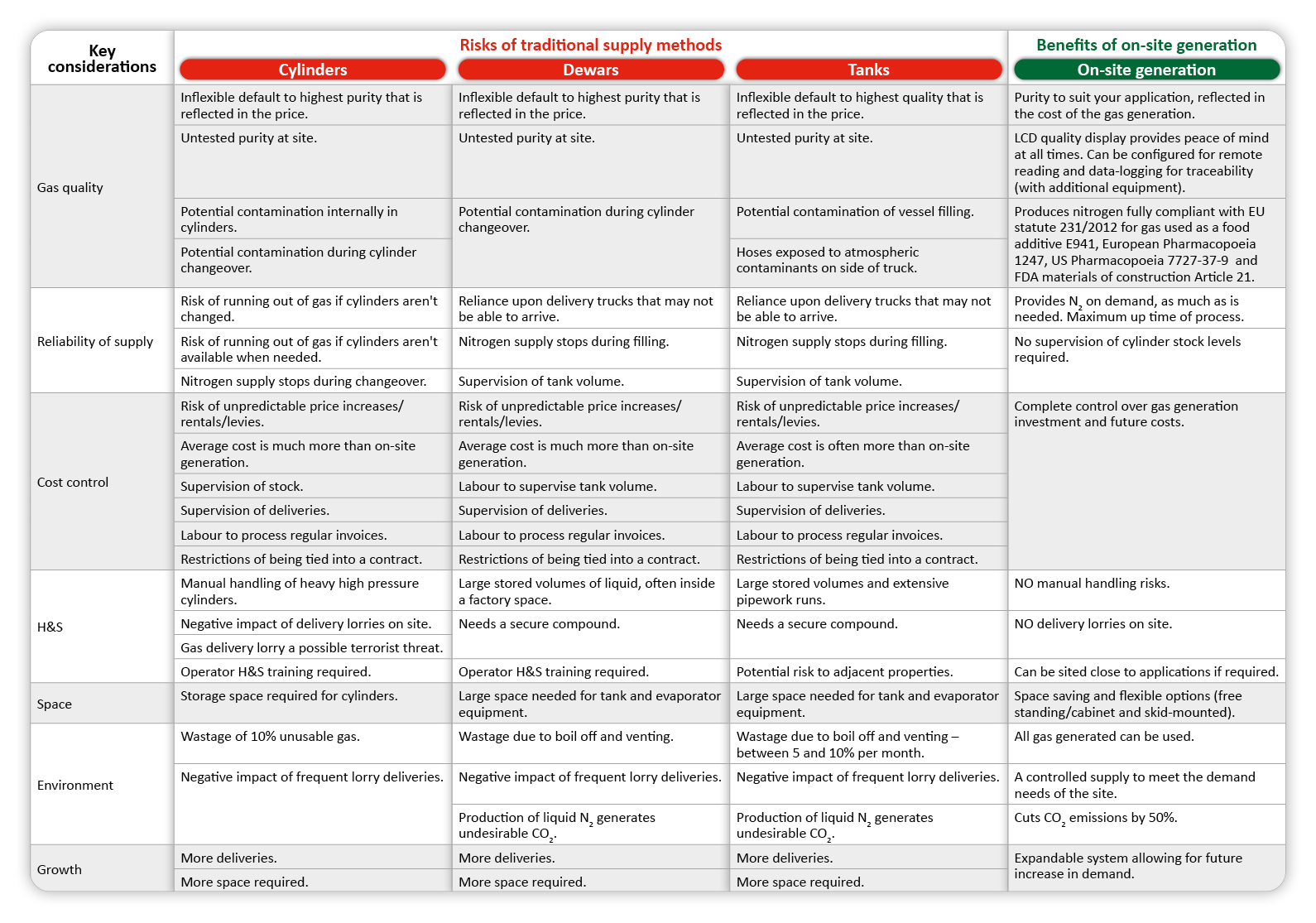

On site gas generation enables you to produce your total demand for nitrogen gas on YOUR premises under YOUR complete control. Quality and volume on demand. As a result you can generate as much or as little nitrogen as needed. Nitrogen generation packages are available as capital purchase or for long term rental to suit your budgets and facilitate planning.

Positive contribution to the bottom line

When the true costs of traditionally sourced nitrogen are accounted for, gas generation is the most economical source of nitrogen as seen in the diagram above. When you switch to gas generation, you can expect payback within 6 to 24 months, depending on your existing arrangements and consumption. But you’re also making an investment in quality through uninterrupted supply, stable gas pressure, consistent flow and guaranteed purity.

Sustainable for the environment

Gas industry sources indicate that an air separation plant uses 1976kJ of electricity to produce 1kg of liquid nitrogen. Generation of 99.9% nitrogen gas in house using a PSA system is 1420 kJ. That means that up to 28% fewer greenhouse gases are created by the generation of electricity with a typical nitrogen generator. At a purity of 98%, the energy required for in house nitrogen drops to 796 kJ/kg. That means that in house generation creates 62% fewer greenhouse gases from electrical power at that purity.

|

Some key benefits of N2 generation on site |

|||||

|

Energy & cost saving |

Quality |

Logistics |

Space |

Environment |

H&S |

|

Generate on demand |

Purity on demand |

Operational reliability |

No cylinder storage |

No production of liquid N2 |

No manual handling |

|

Purity on demand |

LCD quality display |

Generate on demand |

No liquid tank storage |

Reduced tanker movement |

Reduced tanker movement |

|

No wastage |

No default to highest purity |

No stock monitoring |

Skid-mounted option |

|

|

|

Not affected by gas prices |

EIGA food grade |

No delivery limitations |

|

|

|

And just in case you didn't know the science.....

Nitrogen gas makes up about 78 percent of the Earth’s atmosphere and is applied in a variety of industrial uses from the food industry to drug manufacturing. Nitrogen gas is a compound that forms from elemental nitrogen, found throughout the planet’s atmosphere and in most biochemical reactions. One of nitrogen’s unique properties is its ability to form multiple bonds with various other elements and compounds. This has made it incredibly versatile. It is commonly used in industry as a clean, dry, inert gas primarily for displacing oxygen from products and/or processes. Industrial applications in food, material processing, pharmaceuticals and electronics include:

- Packaging in the food and beverage industry to prevent oxidation and spoilage of food and drink.

- Manufacturing transistors, circuits and diodes.

- In manufacturing steel to prevent oxidation.

- Welding and metalworking to prevent oxides and waste compound formation.