Electronics

Inert Nitrogen delivers the clean and dry environment needed for electronics manufacturing

The applications of nitrogen in electronic components

One of the most important consideration for electronic component manufacturers is how to maximise the efficiency of their processes to provide high quality finishes and functionality. Nitrogen can help with the achievement of this goal in several ways, we have included a few of the biggest wins below:

Reduces Impurities

When soldering takes place, solid impurities in the metal can cause a significant issue. Nitrogen can be used to reduce the formation of dross during the wave soldering process, resulting in cleaner and better solder joints.

Prevention of oxidation

Nitrogen creates an inert atmosphere which helps minimize the formation of oxides on the surface of metals during the wave soldering process.

Component storage and handling

Storing components in a nitrogen environment prevents the build-up of moisture and oxidation, increasing the longevity and long-term reliability of individual components.

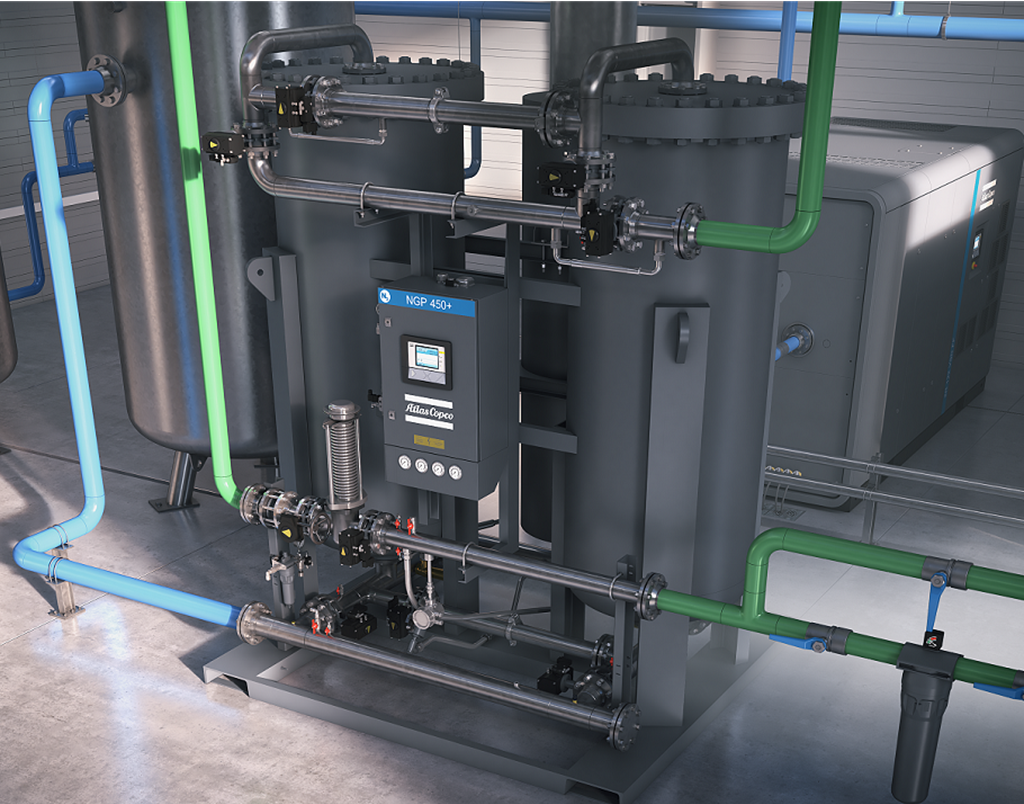

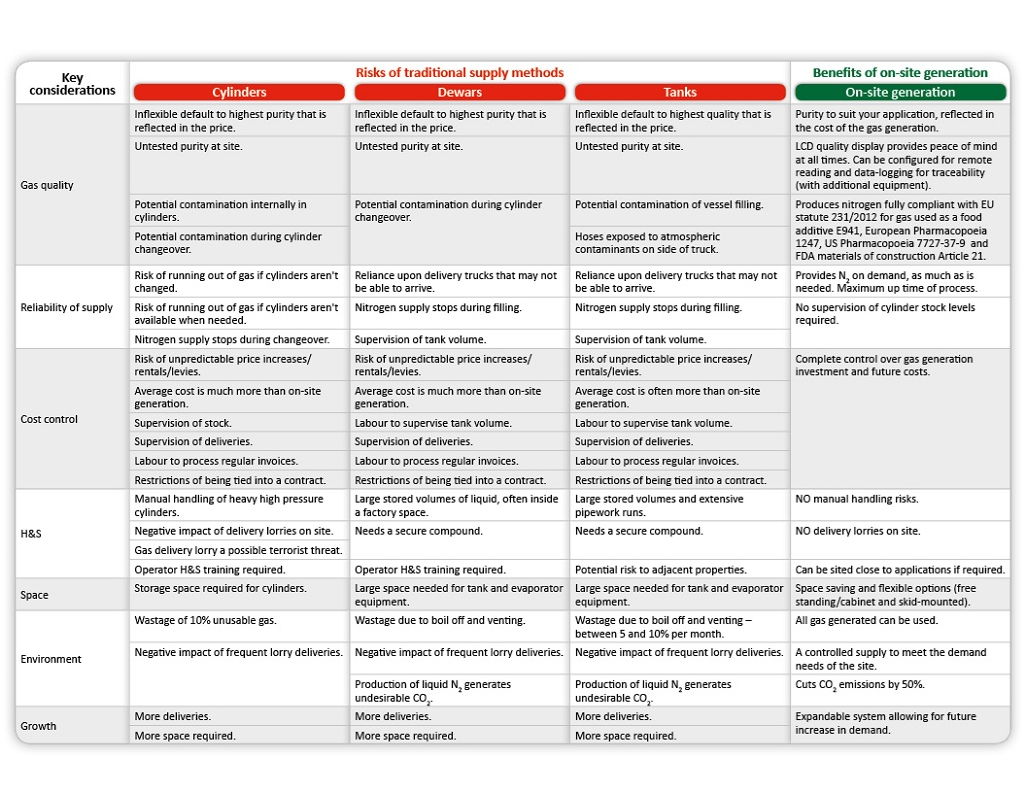

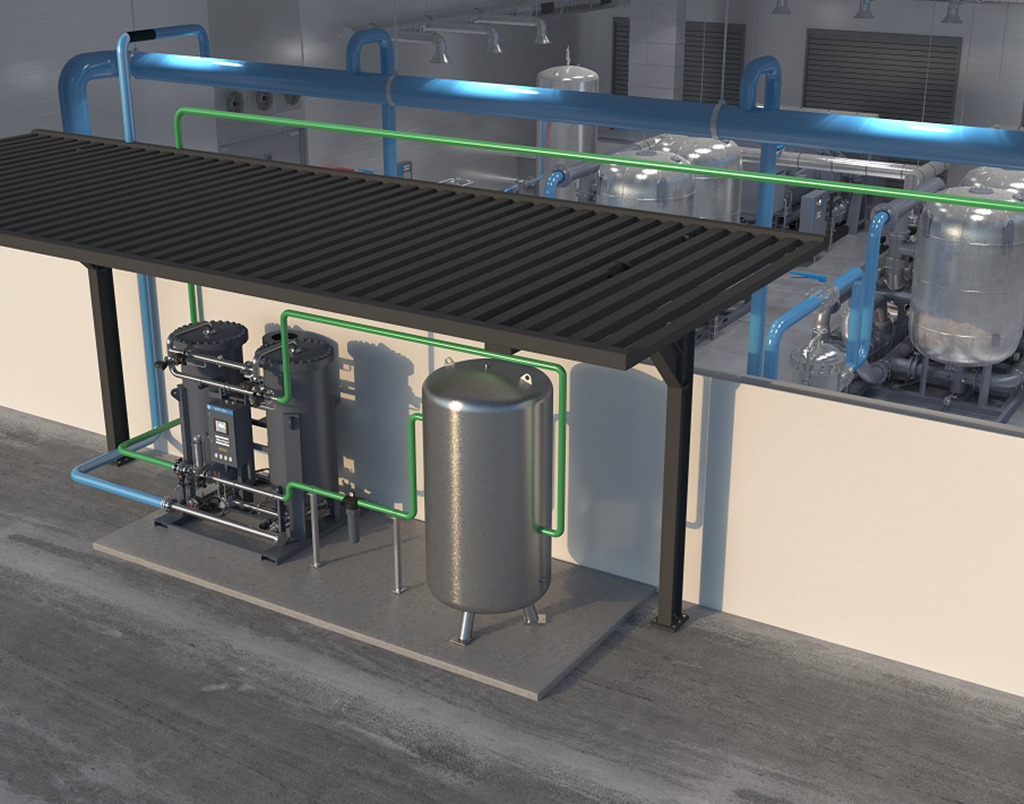

The Maziak Promise

A well-regulated environment is key for any manufacturing industry, and having an on-site nitrogen generator means having easy access to the best solution. All of our generators are fully compliant with EU and USA statute specifications, and on top of this and helping to create the optimal manufacturing environment, nitrogen generators will also help you save on your energy!

Nitrogen is an inert gas used by many electrical component manufacturers thanks to its ability to create a clean and dry environment. This avoids the process of oxidisation and dross formation in the wave soldering process when assembling PCB’s. This ensures a clean and accurate finish is maintained, which is vital in electronic manufacturing.

For more information, please call 01933 222000 or email us at enquiries@maziak.co.uk