"Wave" goodbye to high inert gas costs in your soldering process

The Challenge

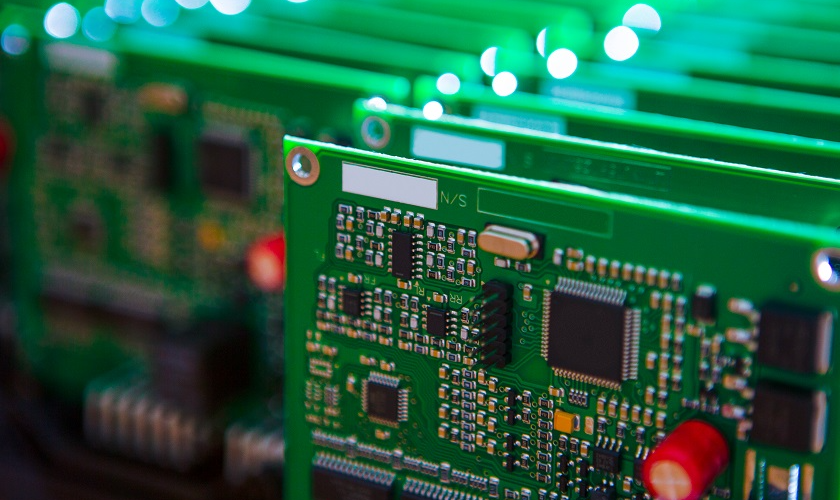

Established in 2011, Electronic Assembly Services (EAS), part of the Express Circuits Group, are one of the leading contract manufacturers of PCB (printed circuit boards) in the UK, counting BAE, Rolls Royce, Selex, Thales and Alstom among their regular clients.

Nitrogen gas is used in the wave solder process to provide an inert atmosphere and prevent oxidisation of the material as it is applied to adhere the components to the PCB. The purity of the inert Nitrogen gas is very important as any Oxygen ingress would render the product useless.

Their existing gas was supplied from 180 litre liquid dewars that were regularly topped up by a tanker delivery which took time and effort to manage and control. Operating in a highly price sensitive market, the rising costs of labour and the liquid supply were getting out of control and cost reduction was the main driver for this site.

The Solution

Key outcomes required by EAS included:

- High purity gas supply of ≤100ppm or 99.99% minimum standard

- Dedicated compressor as the site machines were unsuitable

- All within a secure weatherproof container to be housed outside.

Maziak designed a containerised on-site N2 gas generation system. This comprised of a “bullet proof” HPC SM16 10bar compressor and Parker NITROsource Compact gas generator package delivering high purity gas to the nearby factory via the existing copper piped infrastructure.

The package was assembled off-site ensuring minimal downtime and inconvenience to EAS. Within the container Maziak installed electrical distribution, ventilation and cold weather protection. To ensure the safety of staff operating the equipment, a calibrated ambient Oxygen level alarm system was provided that gives a visual and audible indication if low Oxygen levels exist within the container prior to entry.

The Result

Installation on site took just 4 hours!

All of EAS’s desired outcomes were comprehensively met and the package is now fully operational 24/7.

- No more delivery vehicles so the time and effort required to manage the site’s gas needs can be put to more productive use.

- Continuous availability of supply of on-demand High Purity Nitrogen gas.

- Full responsibility for maintenance is with Maziak and the package is covered by a comprehensive 5 year service and manufacturer backed warranty package.