Pulling out the stops to get it all bottled up

The Challenge

Belvoir Fruit Farms have been creating their thirst-quenching cordials for over 30 years. First they infuse, press and cook fresh flowers, fruits and spices and then blend them with local spring water to make delicious drinks to an exceptional quality using traditional methods.

Due to expansion, the customer was fitting out a new state of the art facility, two miles from the existing site.

The Solution

Based on specifications from the customer plus investigation from Maziak, the new system included:

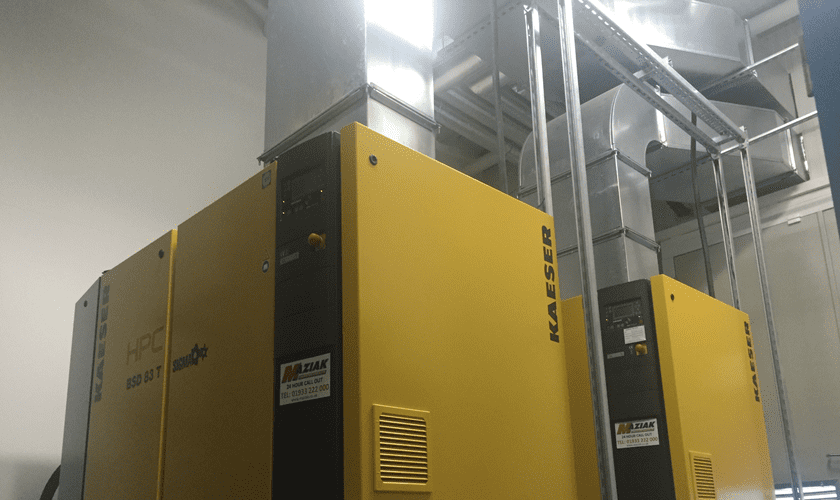

Compressors

- 2 x HPC BSD83T compressors that are configured to automatically switch to supply the full air demand week on week off. The off duty machine will activate if extra air is needed or in the event of a problem.

- Plus air receiver, condensate management filtration and written schemes.

- The existing compressor was installed free of charge as an additional emergency back-up.

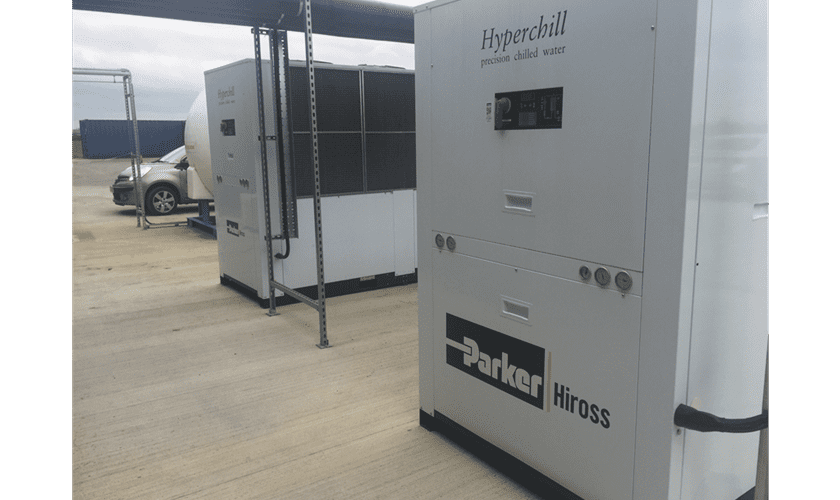

Chillers

These were selected after a careful evaluation of the different processes and heat-loads to ensure correct sizing of the Parker machines:

- 1 x ICE230 feeding the lines for the bottling process

- 1 x ICE360 feeding a flash pasteurizer

Both chillers have intelligent capacity control. With independent dual circuits they operate with stepped loading making them highly energy efficient and ensuring no wasted running time.

Both come with an integral pump and tank saving significant installation costs as there is no requirement to install a separate tank with a pump station.

The Result

The standards expected by the customer to uphold their traditional methods within their new state of the art facility were readily met by Maziak, particularly in terms of the quality and innovation of the product. Peace of mind also comes with Parker’s 3 year warranty on chillers and HPC’s 5 year no quibble on the compressor equipment.

What they said

"It was a pleasure working with Maziak and we would welcome the opportunity to work with them again on future projects."

Frank Fitzgibbons, Production Director