Buying bulk? Let the new generation take over

The Challenge

The customer is the number one wine company in Australia and the UK by volume, and the fifth largest in the world. Their UK production plant, operates six packing lines, with a capacity of filling the equivalent of 1,200 bottles per minute. Over 600,000 bottles per day!

Attracted by the possible cost and environmental savings Maziak were showcasing at the PPMA show in 2016, they wanted to explore how they might reduce their reliance on expensive bulk liquid gas. Following in-depth discussions and analysis of data from their existing processes, Maziak were able to provide a gas generation solution with an attractive payback on the investment.

The Solution

The new installation produces high quality, Food Grade Nitrogen on demand at a fraction of the price of the previous bulk liquid system. The key elements of the install feature the latest in HPC Variable Speed Compressor technology centrally controlled with a SAM 4.0 intelligent controller. Compressed air is cleaned and dried with Parker’s new range of OIL-X filters prior to flowing through to the generation units. The clean, dry, oil free air is then delivered to the Nitrogen generators where the Oxygen is removed and the remaining Nitrogen gas is finally sterilised before supplying the customer’s production plant.

The Result

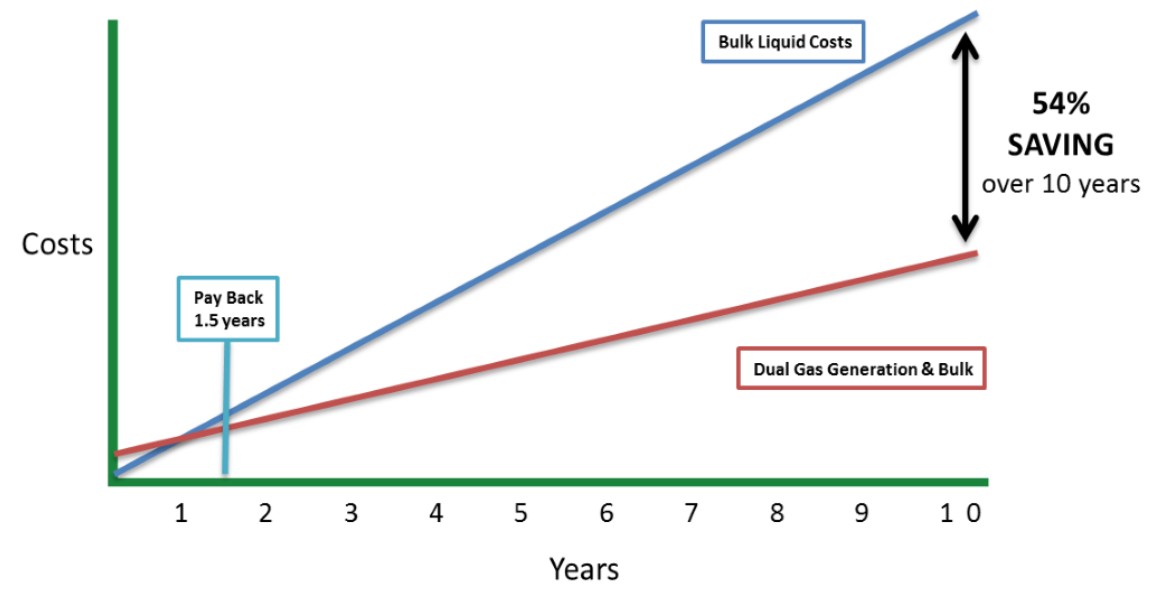

54% savings are predicted, whilst delivering High Quality Food Grade Nitrogen Gas. Payback period is under 1.5 years.

Additional benefits include a two thirds reduction in CO2 emissions compared to a delivered bulk supply and the reassurance of continuity of production that comes with in-house control of gas generation.